Important process conditions to ensure smooth surface of injection molded parts

Ensuring a smooth surface finish on molded parts is a crucial goal in injection molding production, and raw material selection and pretreatment are fundamental to achieving this. First, plastic raw materials with high purity and uniform particle size should be selected to avoid contamination with impurities or foreign matter. Impurities can disrupt the uniformity of the melt during the injection molding process, leading to surface defects such as spots and scratches on the molded part, severely impacting the surface finish. For example, when producing transparent plastic parts, trace amounts of dust or metal debris in the raw materials can result in noticeable surface flaws after molding. Secondly, highly hygroscopic plastics, such as PA and PC, must be thoroughly dried. Moisture vaporizes during the high-temperature melting process, forming bubbles. These bubbles rupture, leaving pits on the surface of the part. Furthermore, moisture can cause material degradation and produce defects such as silver streaks. Drying requires strict temperature and time control. Typically, PA66 requires drying at 120°C for 4-6 hours to ensure a moisture content below 0.05% to ensure a smooth surface finish.

The parameters of injection molding equipment have a direct and significant impact on the surface finish of plastic parts, with melt temperature control being particularly critical. Different plastics have varying melt temperature ranges. If the temperature is too low, the raw material won’t fully melt, resulting in poor melt flow. This excessive flow resistance can cause eddies or cold spots when filling the mold cavity, leading to surface roughness. If the temperature is too high, the material will thermally degrade, producing small volatile molecules. These substances adhere to the mold cavity and part surfaces, causing oily spots or scorch marks. For example, ABS plastic has an optimal melt temperature of 200-250°C. When the temperature exceeds 260°C, the rubber phase is prone to degradation, resulting in a dull, grayish appearance on the part surface. Proper injection speed regulation is also essential. At low injection speeds, the melt front cools too quickly, easily forming an uneven solidification layer. At high injection speeds, turbulent air flow can entrain the material, creating bubbles or silver streaks. Usually, a stepped injection speed is selected according to the structure of the plastic part. For example, for thin-walled parts, a higher speed is used in the initial stage to ensure rapid filling, and the speed is reduced in the final stage to reduce stress, thereby ensuring a smooth surface.

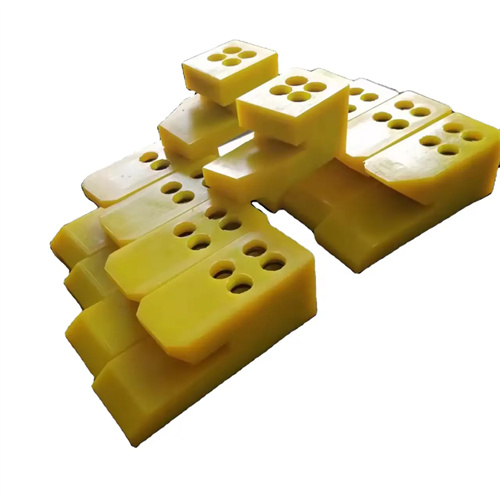

The quality of mold design and maintenance is a key factor in determining the surface finish of a plastic part. The surface condition of the mold cavity is directly replicated on the part surface. Therefore, the cavity requires fine polishing, generally achieving a mirror finish with an Ra value within 0.02-0.05μm. During polishing, avoid scratches left by coarse-grit sandpaper, as these can create corresponding streaks on the part surface. Furthermore, the mold’s gate and runner design should ensure smooth melt flow and avoid shear stress concentration. For example, a fan-shaped gate can evenly distribute the melt at the cavity entrance, minimizing sudden changes in flow direction. A circular runner cross-section reduces flow resistance and prevents surface defects caused by intense melt impact. Furthermore, the mold’s cooling system must ensure uniform temperature. Uneven cooling can cause internal stress on the part surface due to uneven shrinkage, leading to warping or gloss variations. Cooling channels should be located close to the cavity surface, with spacing of 20-30mm between them. This ensures consistent cooling rates across the part and prevents surface darkening caused by localized overheating.

Process control during the holding stage is crucial for eliminating surface defects and improving surface finish. Properly setting the holding pressure and holding time can compensate for volumetric shrinkage during melt cooling, preventing sink marks or depressions on the surface. The holding pressure is typically 60%-80% of the injection pressure. If the pressure is insufficient, the part won’t receive sufficient melt replenishment during cooling and shrinkage, resulting in shrinkage lines on the surface. Excessive pressure can cause flashing or increased internal stress, leading to surface cracking. The holding time should be determined based on part thickness. Generally, thick-walled parts require a longer holding time to ensure adequate shrinkage compensation in the center. For example, for a 5mm thick PP part, the holding time should be controlled within 15-20 seconds to avoid sink marks. Temperature control during the holding stage is also crucial. Slowly lowering the barrel temperature can reduce melt backflow, maintain a stable feeding pressure, and further ensure a smooth surface finish.

Cleanliness and process stability in the production environment are also crucial for ensuring surface finish. Any minor external disturbance can affect the final result. The production workshop must be dust-free, especially when producing high-quality plastic parts. Cleanroom production should be used, and the concentration of airborne dust particles below 0.5 μm should be controlled to no more than 3,520 particles per cubic meter. During mold installation, the cavity should be protected from oil and fingerprints. Before closing the mold, the cavity surface should be wiped with a dedicated cleaner to prevent impurities from adhering. Regular maintenance of the injection molding machine is also crucial. Wear on the screw and barrel can lead to uneven melt plasticization. Cold material at the nozzle must be promptly removed to prevent it from entering the cavity and causing surface defects. For example, when the screw clearance exceeds 0.3 mm, melt backflow is likely to occur, resulting in unstable filling and surface ripples. Therefore, regular inspections of equipment accuracy and cleaning of barrel residues can provide continuous assurance of stable surface quality.