Injection molded wire duct design

When designing injection-molded cable troughs, the design must prioritize the intended use environment and cable routing requirements. Ensure the trough provides adequate space and protection to prevent cable damage during use. The trough’s dimensions should be determined based on the number of cables, their diameters, and bend radius. For example, for a single 5mm diameter cable, the trough should be at least 8mm wide and 6mm deep to ensure smooth cable routing and sufficient room for movement. For multiple cables, at least 20% of excess space should be reserved to prevent compression and insulation wear. For example, when laying three 3mm diameter cables simultaneously, the trough’s cross-sectional area should be at least 3 × (3/2)² × π × 1.2 ≈ 42mm². Furthermore, the trough’s path should be as gentle as possible, avoiding sharp turns. The turning radius should be at least five times the cable diameter. For a 4mm diameter cable, the turning radius should be at least 20mm to prevent breakage due to excessive bending. In humid or dusty environments, the cable duct needs to be designed with a sealed structure. Rubber sealing rings or snap-on covers can be used to prevent moisture and dust from entering and affecting cable performance.

The structural strength of injection-molded cable ducts is a key design consideration. It must ensure they resist deformation or fracture during assembly and use due to stress. This is especially true at the connection between the duct and the main plastic component, where reinforcement should be implemented. The wall thickness at this connection should be 1.5-2 times thicker than the duct itself. For example, if the duct’s wall thickness is 2mm, the wall thickness at the connection should be 3-4mm. Ribs should be designed with a height of 2-3 times the wall thickness and a width of 0.5-0.7 times the wall thickness to enhance the connection. The edges of the duct should be rounded with a radius of at least 0.5mm to prevent sharp edges from scratching cables or operators. For cable ducts that need to withstand a certain amount of tension, such as in situations where cables are frequently plugged in and out, anti-slip protrusions or clamping structures need to be designed at the cable outlet. For example, an elastic buckle can be set at the end of the cable duct to automatically clamp the cable when it passes through to prevent it from being accidentally pulled out. At the same time, the elastic deformation of the buckle should be controlled between 0.5-1mm to ensure the clamping effect and facilitate the installation and removal of the cable.

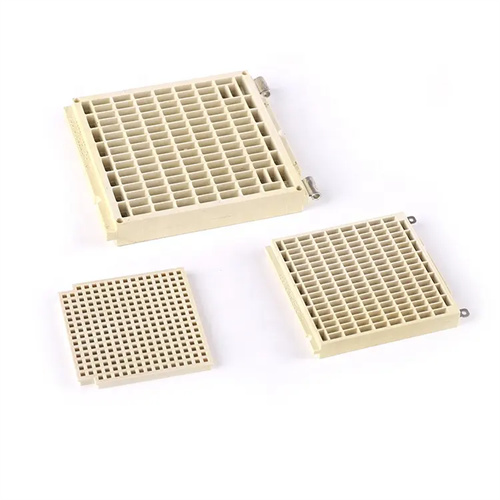

The demolding design of injection molded wire troughs is crucial to production efficiency and part quality. The mold structure must be simple, allowing the trough to be smoothly demolded to avoid burrs or deformation. The sidewalls of the trough should be designed with a sufficient draft angle, typically 1°-3°. For troughs with lower surface roughness, the draft angle can be reduced appropriately. For example, for molds with mirror polish, a draft angle of 1° is sufficient, while for molds with rougher surfaces, a draft angle of 2°-3° is required. If the trough is a closed structure, a lateral core-pulling mechanism must be installed on the mold. The core-pulling direction should be aligned with the axis of the trough, and the core-pulling distance should be greater than the depth of the trough. For example, for a closed trough with a depth of 10mm, the core-pulling distance should be at least 12mm to ensure smooth demolding. The connection between the bottom of the outlet groove and the main body of the plastic part should avoid sharp corners and can be designed as an arc transition, which is conducive to melt flow filling and can also reduce resistance during demoulding. For example, the radius of the transition arc is 1-2mm, so that the melt can flow smoothly during the filling process and avoid bubbles or material shortages.

The material selection for injection-molded cable ducts should be determined based on application requirements. Different plastic materials have varying mechanical properties and environmental resistance, which directly impact the duct’s service life and reliability. For lightweight cable ducts used in general environments, polypropylene (PP) or polyethylene (PE) are suitable. These materials offer excellent toughness and processability, are relatively low-cost, and are suitable for simple cable ducts in household appliances. For applications requiring higher strength and temperature resistance, such as cable ducts within automotive engine compartments, nylon (PA66) or polybutylene terephthalate (PBT) reinforced with glass fiber should be used. These reinforced materials offer tensile strengths of 80-100 MPa and an operating temperature range of -40°C to 120°C, making them suitable for use in harsh environments. For cable ducts requiring flame retardancy, such as cable protection ducts within electronic equipment, flame-retardant-grade plastics, such as flame-retardant ABS or flame-retardant PC, should be selected. Their oxygen index should be at least 28, effectively slowing the spread of flame and improving safety.

The assembly and compatibility design of injection-molded cable troughs must consider coordination with other components, ensuring a seamless fit with cables, connectors, and other components for easy installation and maintenance. The cable troughs and connectors should utilize a transition fit, with a clearance of 0.1-0.2mm to ensure a tight connection and easy insertion and removal. For example, the outlet diameter of the cable trough should be 0.15mm larger than the outer diameter of the connector to ensure smooth insertion and removal. The length of the cable trough should be determined based on the cable routing path. Excessive length will result in material waste and assembly inconvenience, while excessive shortness will not effectively protect the cable. The trough should generally be 5-10mm longer than the cable’s run length within the molded part, allowing for sufficient adjustment. Furthermore, the cable troughs can be designed with locating holes or clips to secure the cables and prevent them from moving during use. The diameter of the locating holes should be 0.5-1mm larger than the cable diameter, and spaced 50-100mm apart to ensure a secure cable connection. For cable ducts that require frequent maintenance, they can be designed with a detachable structure, such as using snap connections or screw fixes, to facilitate opening for cable inspection and replacement, thereby improving the maintainability of the product.