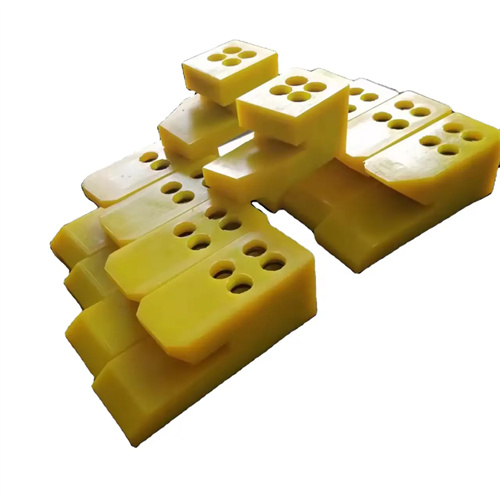

Injection Molded Spiral Column Specifications

Injection-molded spiral studs are common functional structures in plastic parts, widely used in transmission, connection, and adjustment applications. Their specifications must be designed to meet strength, fit, and molding process requirements. Spiral stud specifications include diameter, pitch, lead, length, and thread profile. Each parameter has clear design standards and selection principles. Proper specification design ensures optimal performance while minimizing molding complexity.

The diameter specifications of a screw thread are determined based on its load-bearing capacity and installation space, and primarily include the major diameter, the middle diameter, and the minor diameter. The major diameter is the maximum diameter of the screw thread and directly affects its strength and appearance. It is typically calculated based on the axial and radial forces it withstands, using the following formula: Major Diameter = (Axial Force × Safety Factor) ÷ (Material Allowable Stress × Pitch). For example, a screw thread must withstand an axial force of 500N. It is made of ABS material (allowable stress 40MPa), has a pitch of 2mm, and a safety factor of 1.5. The major diameter is ≈ (500 × 1.5) ÷ (40 × 2) ≈ 9.375mm, which can be rounded to 10mm in actual design. The middle diameter is a key parameter determining the screw thread’s performance, generally ranging from 0.85 to 0.9 times the major diameter, while the minor diameter is 0.7 to 0.8 times the major diameter, ensuring sufficient thread strength.

Pitch and lead are key motion parameters of a helical screw. Pitch is the axial distance between corresponding points on the mid-diameter line of two adjacent threads, while lead is the axial distance between corresponding points on the same helical line (lead = pitch × number of threads). The pitch specification is selected based on the speed and precision requirements of the helical screw. Commonly used standard pitches include 1mm, 1.5mm, 2mm, and 3mm. Small pitches are suitable for high-precision fine-tuning mechanisms, such as those used in instrumentation, while large pitches are suitable for rapid transmission, such as the lifting mechanisms used in toys. For example, for a helical screw requiring rapid lifting, a 3mm pitch, double-start thread, and 6mm lead are used, resulting in 6mm of movement per rotation, significantly improving transmission efficiency.

The length specifications for a screw stud include thread length and total length. The thread length is determined based on the depth of the fit and should generally be 1–2 pitches longer than the thread length of the mating component to ensure a secure fit. The total length is determined by the installation space and travel range, with ample guide space required to prevent the screw stud from tilting during movement. For example, if the mating component has a 20mm thread length, the screw stud can be designed with a thread length of 22–24mm. Based on a 30mm travel range, the total length is designed to be 50mm (24mm thread length + 26mm guide portion). Furthermore, the end of the screw stud is typically tapered or spherical to facilitate guidance during assembly, with a taper angle typically ranging from 30° to 60°.

The thread profile of a screw thread should be selected based on the intended use. Common thread profiles include triangular, trapezoidal, and rectangular. Triangular threads offer excellent self-locking properties and are suitable for connection applications, such as fastening screw threads in plastic parts. Trapezoidal and rectangular threads offer high transmission efficiency and are suitable for transmission applications, such as paper feed screws in printers. The thread angle should also be designed to match the material properties. Tough plastics (such as PE and PP) can use a 60° thread angle, while rigid plastics (such as PS and ABS) can use a 55° thread angle to reduce stress concentration during molding. For example, a screw thread for connection made of ABS material uses a 60° triangular thread profile with a crest width of 0.38mm and a root width of 0.25mm to ensure thread strength and self-locking properties.

When determining the specifications of spiral studs, the feasibility of the molding process must also be considered. Excessively fine threads (e.g., a major diameter less than 3mm) may make molding difficult, requiring an increased demolding angle or forced demolding. Excessively long threads (e.g., exceeding 10 times the diameter) may result in insufficient filling or warping during molding, requiring optimization of the mold’s gating position and cooling system. For example, a spiral stud with a major diameter of 5mm and a length of 60mm is prone to bending during molding due to its aspect ratio of 12. By incorporating a spiral guide mechanism into the mold and enhancing cooling, molding accuracy is ensured. At the same time, spiral stud specifications should utilize standardized parameters whenever possible to reduce custom processing costs and improve interchangeability.