Gas-assisted injection molding

Gas-assisted injection molding (GAIM) is an advanced process that uses high-pressure gas to propel the melt into the mold cavity. Compared to traditional injection molding, it reduces melt usage, shortens molding cycles, and reduces internal stress in the product. It is particularly suitable for large, thick-walled products (such as appliance housings and automotive parts) and parts with complex structures. The core of this process is to use gas to create hollow channels within the melt, enabling pressure transmission and pressure-maintaining shrinkage compensation. This eliminates common defects in traditional injection molding, such as sink marks, warping, and sink marks. It also reduces the clamping force required, expanding the application range of injection molding.

The basic process of gas-assisted injection molding consists of four stages: melt pre-filling, gas injection, gas pressure holding, and demolding. The parameters in each stage directly affect the molding effect. During the pre-filling stage, the melt must be injected into the mold cavity to a level of 60% to 90% (adjusted according to the product structure). Excessive filling prevents the gas from penetrating and forming air channels, while too little filling can easily lead to material shortages. For example, the pre-fill level for an air conditioning panel (wall thickness 3 to 5 mm) is 75%. This ensures that the gas can evenly push the melt into the mold cavity while preventing excessive air channels from affecting structural strength. During the gas injection stage, high-pressure nitrogen (5 to 30 MPa) is introduced before the melt fully solidifies. The gas enters the mold cavity through a dedicated valve and propels along the path of least resistance (usually the thick-walled area), forming a continuous air channel. At this stage, the gas injection rate must be controlled to match the melt flow rate to prevent turbulence and surface defects in the product.

Setting gas pressure and holding time is crucial for process control. Pressure should be determined based on the plastic type and part wall thickness. For low-viscosity plastics (such as PE and PP), the gas pressure should be 5-15 MPa, while for high-viscosity plastics (such as PC and POM), it should be 15-30 MPa. Excessively high pressure can cause flash, while too low a pressure cannot effectively compensate for shrinkage. The holding time should ensure that the gas pressure is fully transferred to the melt to compensate for cooling shrinkage. For thick-walled products, the holding time is 10-20 seconds, while for thin-walled products, it is 5-10 seconds. For example, a PP washing machine inner drum (maximum wall thickness 8mm) uses a gas pressure of 18 MPa and a holding time of 15 seconds. This eliminates sink marks and reduces the weight of the part by 12% compared to traditional injection molding. After the holding period, the pressure should be released slowly (for 2-5 seconds) to avoid sudden pressure drops that could cause part deformation.

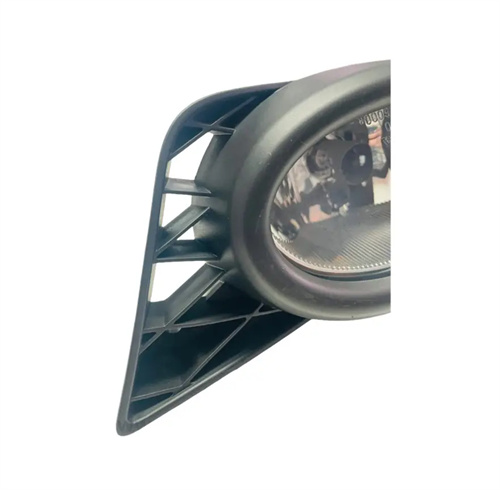

Gas-assisted injection molding (GAIM) imposes special mold design requirements, requiring the proper placement of air ducts and inlets. Air ducts should be arranged along the thickness of the part wall, with a circular or elliptical cross-section (3-8mm diameter) to ensure smooth gas penetration. Air inlets should be located at the final fill point of the cavity or at the center of the thick wall. For example, inlets with a diameter of 1-3mm should be placed at the end of a rib or at the bottom of a boss to prevent direct gas impact on the cavity surface, creating air marks. For large parts (such as automobile bumpers), multi-point air inlet can be used, with inlet spacing of 50-100mm. Sequential control ensures uniform gas distribution. The mold venting system should be enhanced, with venting slots 0.02-0.03mm deep and 10-20mm wide to promptly expel any residual air displaced by the gas and prevent trapped air from causing burns.

Gas-assisted injection molding equipment consists of a dedicated gas generator, a pressure control system, a gas valve, and an injection molding machine. The gas generator must provide stable high-pressure nitrogen (purity ≥99.9%) with a pressure fluctuation of ≤±0.5 MPa. The pressure control system can precisely adjust the injection and holding pressures with a response time of ≤0.05 seconds. The gas valve must have a fast opening/closing function (opening and closing time ≤0.1 second) to ensure precise timing of gas injection. For example, the gas-assisted system equipped on one production line has a pressure control accuracy of ±0.2 MPa and can store 100 sets of process parameters to meet the production needs of a wide variety of products. The connection between the equipment and the mold must be reliably sealed. The air inlet pipe should be made of pressure-resistant stainless steel (operating pressure ≥40 MPa), and the joints should use compression fittings to prevent high-pressure gas leakage.

The advantages of gas-assisted injection molding are particularly prominent in specific areas. In terms of material savings, the use of air channels can reduce melt usage by 10%–30%. For large products (such as plastic parts weighing over 10kg), a single mold can significantly save raw material costs. In terms of molding cycle, gas pressure retention replaces melt pressure retention, shortening cooling time by 20%–50%. For example, the molding cycle of a television housing was reduced from 50 seconds to 30 seconds. In terms of product performance, internal stress is reduced by 30%–50%, and warpage is reduced by 40%–60%. For example, the warpage of a PP automotive door panel was reduced from 2mm to 0.8mm. However, this process also has disadvantages such as high equipment investment (30%–50% higher than traditional injection molding) and complex debugging. It is suitable for the production of large-volume, high-value-added products. With technological advances, gas-assisted injection molding is moving towards intelligentization, further improving process stability and application scope through mold flow analysis and real-time monitoring.