Injection molding machine adjustment skills: pressure and speed fine-tuning method

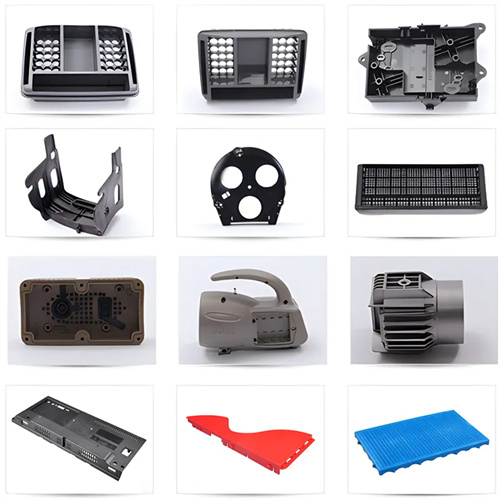

During injection molding machine tuning, fine-tuning pressure and speed is a key technique for ensuring consistent part quality. This approach relies on precisely adjusting parameters such as injection pressure, holding pressure, and injection speed to optimize the melt flow and solidification process within the mold cavity, thereby resolving various defects that may arise during part production. Compared to drastic parameter adjustments, fine-tuning emphasizes incremental optimization, enabling gradual improvement in part quality while avoiding new defects. For example, when a part exhibits slight sink marks, blindly increasing holding pressure can lead to flash. However, fine-tuning the pressure by 0.5-1 MPa, combined with coordinated adjustments to the speed parameters, can eliminate sink marks while maintaining production stability. This refined adjustment method is particularly suitable for the production of precision plastic parts (such as medical components and electronic components), enabling dimensional errors to be controlled within 0.01 mm.

Fine-tuning the injection pressure should be performed in stages based on the structural characteristics and defect types of the part. Fine-tuning during the filling phase primarily addresses issues like material shortages and weld marks. If underfill occurs in the corners of the part, the injection pressure can be increased by 1-2 MPa at a time while observing the flow of the melt front until complete filling is achieved. If weld marks are noticeable, the filling pressure can be reduced by 5-10%, and the melt confluence time can be increased to reduce interfacial stress. Fine-tuning during the holding phase focuses on sink marks and dimensional accuracy. If surface depressions appear on the part, the holding pressure can be increased in increments of 0.5 MPa per injection. After each adjustment, 5-10 molds should be run continuously, and the holding effect verified by weighing. If the part is oversized, the holding pressure can be reduced by 1 MPa and the holding time extended by 5-10 seconds to prevent volume expansion caused by a sudden pressure drop. For example, in the production of polycarbonate (PC) water cups, fine-tuning the holding pressure from 30 MPa to 32 MPa successfully eliminated sink marks on the cup bottom without causing flash.

Fine-tuning the injection speed must be coordinated with pressure parameters, adhering to the principle of “low speed for steady flow, high speed for filling.” For thin-walled plastic parts, fine-tuning the speed during the initial filling phase is particularly critical. If scorch marks appear near the gate, reduce the initial speed by 5%-8% and increase the melt temperature by 2-3°C to reduce shear overheating. If ripples appear on the side of the part, increase the speed during the mid-speed phase by 3-5 mm/s to enhance melt spreadability. Speed adjustments should be kept within ±10% of the original parameters, and the molding results should be observed for 3-5 molds after each adjustment to avoid bubbles or silver streaks caused by sudden speed changes. For example, when producing 0.8mm thick polypropylene (PP) sheets, fine-tuning the high-speed phase from 60 mm/s to 63 mm/s, combined with a 1 MPa increase in injection pressure, resolved the issue of material shortages at the sheet edges while maintaining a smooth surface finish.

The order in which pressure and speed are fine-tuned significantly impacts machine setup efficiency, typically following the principle of “speed first, pressure later.” Speed directly determines the melt’s flow pattern. Prioritizing speed optimization quickly determines the optimal filling path, laying the foundation for pressure adjustments. For example, when a weld line appears on a part, fine-tune the speed (e.g., increasing the speed near the weld line by 5 mm/s) to promote melt fusion. If this is ineffective, gradually increase the holding pressure. For crystalline plastics (such as polyoxymethylene (POM), particular attention must be paid to the timing of matching pressure and speed. Just as the melt is about to fill the cavity (approximately 90% fill), the speed should be reduced by 10-15 mm/s, 5-10 mm in advance, while simultaneously increasing the holding pressure by 3-5 MPa to compensate for crystallization shrinkage. This combination of “reducing speed and increasing pressure” fine-tuning can control dimensional fluctuations in POM parts to within 0.02 mm.

Fine-tuning pressure and speed requires a combination of material properties and dynamic optimization of the mold structure. For highly hygroscopic materials (such as nylon PA66), fine-tuning requires increasing back pressure by 0.5-1 MPa and reducing injection speed by 5 mm/s to expel moisture from the melt. For glass fiber-reinforced plastics, the injection speed should be reduced by 10%-15%, while injection pressure should be increased by 5-8 MPa to minimize fiber orientation imbalance. The mold’s cooling system also affects the effectiveness of fine-tuning. If the cavity temperature distribution is uneven, the cooling water temperature should be increased by 2-3°C while reducing the filling speed by 3-5 mm/s in the corresponding area to prevent deformation caused by localized overheating. For example, in the production of glass fiber-reinforced polypropylene (PP+30% GF) gears, fine-tuning the injection speed from 50 mm/s to 45 mm/s, increasing the injection pressure from 80 MPa to 85 MPa, and increasing the mold temperature by 5°C successfully resolved material shortages and cracking in the gear teeth. With the popularization of intelligent injection molding machines, real-time monitoring of the cavity pressure curve can be used to automatically generate fine-tuning suggestions for pressure and speed, shortening machine adjustment time by more than 30%.