Method of Improving the Reliability of Slide Mechanism by Injection Molding

The injection molding slide mechanism (also known as the slider mechanism) is a critical component for achieving side core pulling or side parting in complex molds. Its reliability directly impacts the demolding efficiency and molding quality of the plastic part. The slide mechanism requires frequent reciprocating motion during operation. If its reliability is insufficient, problems such as jamming, excessive wear, and inadequate core pulling can occur. These defects can lead to defects such as strain, deformation, and even mold failure in the plastic part, seriously impacting production progress. Therefore, effective methods to improve the reliability of the slide mechanism are crucial to ensuring continuous and stable injection molding production. For example, in the production of large plastic parts such as automobile bumpers, a slide mechanism failure can cause the production line to shut down for several hours, resulting in significant economic losses. Therefore, improving its reliability has significant economic benefits.

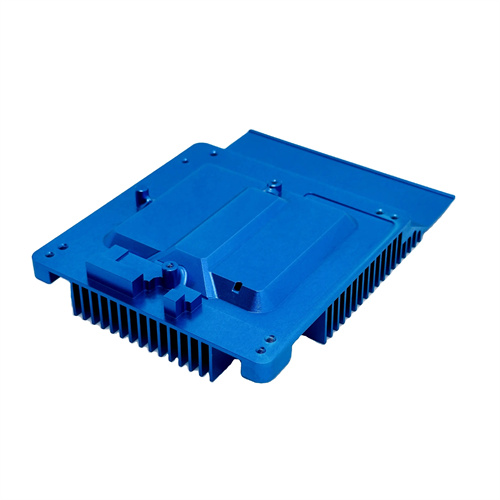

Optimizing the structural design of the slider mechanism is the basis for improving its reliability. The structure of the slider mechanism should be as simple and compact as possible, avoiding unnecessary complex components to reduce failure points. For example, adopting an integrated slider structure instead of a spliced structure can reduce failures caused by loose connections; rationally designing the slider’s guide mechanism and using high-precision guide pins, guide sleeves, or linear guides can ensure the straightness and stability of the slider’s movement and reduce friction and wear during movement. In addition, the core pulling distance and movement speed of the slider mechanism must also be reasonably designed. Excessive core pulling distance may increase the inertia of the slider and increase the impact load during braking; excessive movement speed will increase component wear and shorten service life. Therefore, in structural design, the core pulling distance should be controlled within a reasonable range based on the structural characteristics of the plastic part, and a buffer device (such as a hydraulic buffer) should be used to reduce sudden changes in movement speed.

Selecting the right materials and performing appropriate heat treatment are key to improving the wear resistance and fatigue resistance of the slide mechanism. Core components of the slide mechanism (such as sliders, guide posts, and inclined guide posts) should be constructed from high-strength, high-wear-resistant materials, such as alloy tool steel (e.g., Cr12MoV) and bearing steel (e.g., GCr15). After heat treatments such as quenching and tempering, these materials can achieve a surface hardness of HRC55-60, exhibiting excellent wear resistance and deformation resistance. For example, nitriding of the working surface of the slider can increase surface hardness by over 30%, significantly enhancing wear resistance and extending service life by 2-3 times. Furthermore, for mating surfaces subject to frequent movement, surface treatments such as chrome plating and carbide spraying can be used to further enhance wear and corrosion resistance.

Strengthening the lubrication and maintenance of the sliding mechanism is an important measure to ensure its long-term and reliable operation. During the movement of the sliding mechanism, friction will occur between the matching surfaces of the slider and the guide post, and between the inclined guide post and the slider. If the lubrication is poor, the friction coefficient will increase, causing wear and heat, and even jamming. Therefore, it is necessary to lubricate these matching surfaces regularly, select suitable lubricants (such as high-temperature grease, solid lubricants, etc.), and ensure the cleanliness of the grease to prevent impurities from entering the matching surfaces and aggravating wear. During the maintenance process, the various components of the sliding mechanism should also be regularly checked for looseness, wear, deformation, etc. If the guide post is found to be worn more than 0.1mm or the inclined guide post is bent, the components should be replaced in time to prevent the fault from expanding. For example, for sliding mechanisms that run more than 10 hours a day, it is recommended to conduct a comprehensive inspection every two weeks and replace the lubricant once a month.

The use of advanced detection and monitoring technologies can promptly detect potential faults in the slider mechanism and improve its operational reliability. In mold design, monitoring devices such as displacement sensors and pressure sensors can be installed to monitor the slider’s movement position, movement speed, and force in real time. When abnormal parameters are found, alarm signals are issued in time to avoid failures. For example, by installing a magnetic scale on the slider, the slider’s core pulling distance can be accurately measured. If the deviation between the actual distance and the set distance exceeds 0.5mm, the system will automatically shut down and prompt for maintenance. In addition, vibration analysis technology is used in the production process to monitor the vibration frequency and amplitude of the slider mechanism to determine whether it has abnormal wear or looseness, so that maintenance can be carried out in advance. With the development of industrial Internet of Things technology, the operating data of the slider mechanism can also be uploaded to the cloud management platform to achieve remote monitoring and predictive maintenance, further improving its reliability and service life.