Factors affecting the quality of injection molding products

The quality of injection molded products is influenced by a complex array of factors, from raw material selection to mold design, from process parameter settings to equipment operation. Deviations in any of these steps can lead to dimensional deviations, surface defects, insufficient mechanical properties, and other issues. In actual production, these factors are interconnected and mutually constrained, requiring systematic analysis and precise control to consistently produce high-quality products. For example, differences in the molecular structure of the raw materials can affect melt fluidity, while uneven mold cooling can amplify these differences, ultimately leading to product warping. Therefore, a comprehensive understanding of the various factors influencing product quality is a prerequisite for achieving refined production and quality control.

Raw material characteristics are fundamental factors in determining the quality of injection molded products. Their physical and chemical properties directly impact the molding process and final product performance. The molecular weight and distribution of the resin significantly influence melt flow. Excessively high molecular weight increases melt viscosity, making filling difficult and prone to short-fill defects. Excessively low molecular weight reduces mechanical properties, such as impact strength and temperature resistance. The type and proportion of additives are also crucial. Plasticizers improve the resin’s flexibility, but excessive addition can lead to insufficient strength. Stabilizers prevent resin decomposition at high temperatures, but poor compatibility with the resin can lead to surface precipitates, forming bloom. Furthermore, the moisture content of the raw materials is a key indicator. For example, polyamide (PA) resins are highly hygroscopic. If not thoroughly dried, moisture vaporization during molding can produce bubbles, damaging the surface integrity and internal structure of the finished product. Therefore, rigorous raw material testing is essential before production to ensure that all parameters meet molding requirements.

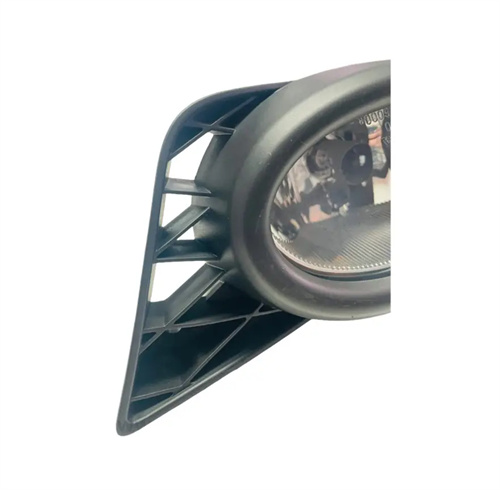

Mold design and manufacturing precision have a crucial impact on product quality. A sound mold structure is crucial for ensuring dimensional accuracy and surface finish. The dimensional tolerances of the cavity and core directly determine the dimensional accuracy of the product. If mold component machining errors exceed the allowable range, the product will be dimensionally out of tolerance and fail to meet assembly requirements. The location and form of the gate influence the melt filling path. For example, edge gates can easily leave gate marks on the part surface, while point gates, while ensuring a pleasant surface, can cause melt degradation due to excessive shear rates. An inadequately designed venting system can prevent air from escaping the cavity, leading to cavitation or burn marks. This problem is particularly prominent at corners in complex parts. Furthermore, mold guiding accuracy and parting surface fit are crucial. Excessive guide clearance can lead to misalignment of the cavity during mold closing, resulting in flash. A loose fit can cause flash, affecting the part’s appearance and dimensional stability.

Setting injection molding process parameters is a key tool for controlling product quality. Even slight variations in parameters such as temperature, pressure, and time can cause quality fluctuations. Barrel temperatures that are too low can lead to uneven melt plasticization, resulting in cold spots within the part. Excessive temperatures can cause resin decomposition , resulting in black spots or bubbles, and compromised mechanical properties. The matching of injection and holding pressures directly impacts part density. Insufficient pressure can lead to incomplete filling or sink marks, while excessive pressure can increase internal stresses, causing cracking or warping. The choice of injection speed should be considered in conjunction with the part structure. High injection speeds reduce melt cooling time and are suitable for thin-walled parts, but can also lead to turbulence and flash. Low injection speeds prevent bubbles and are suitable for thick-walled parts, but can result in surface concavities due to prolonged filling times. Setting the holding and cooling times is equally critical. Insufficient holding time can lead to shrinkage cavities due to insufficient shrinkage compensation. Too short a cooling time can cause deformation after demolding, while excessive cooling times can reduce production efficiency.

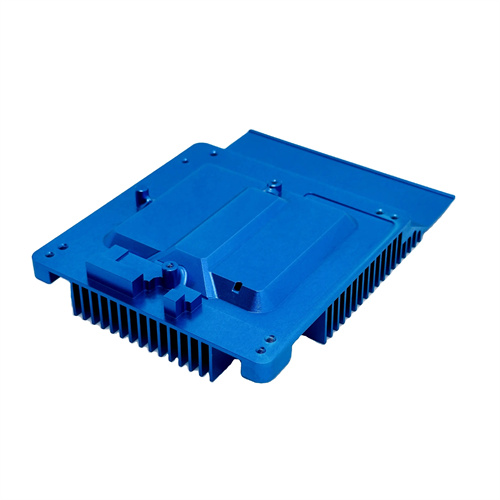

Equipment operating conditions and environmental conditions significantly impact the quality stability of injection molded products. Equipment performance degradation and environmental fluctuations can lead to uncontrolled process parameters. Insufficient clamping force on the injection molding machine can cause gaps in the mold under injection pressure, resulting in flash. Excessive clamping force, on the other hand, can exacerbate mold wear and shorten its service life. The hydraulic system’s pressure stability directly impacts the injection and holding processes. Pressure fluctuations can lead to increased weight variation in parts and reduced dimensional accuracy. Inadequate temperature control accuracy in the heating system can cause temperature deviations between barrel sections to exceed setpoints, disrupting the uniformity of melt plasticization. Fluctuations in ambient temperature and humidity are also important. High temperatures can affect mold cooling efficiency, leading to uneven cooling of parts. High humidity can cause hygroscopic raw materials to absorb moisture again, increasing the risk of molding defects. Furthermore, inadequate regular equipment maintenance, such as screw wear and check ring leakage, can lead to unstable melt delivery, further exacerbating product quality fluctuations.