Pressure of different plastic melts on mold cavity and core

Different plastic melts exhibit significant differences in the pressure exerted on the mold cavity and core during the injection molding process. This variation is primarily due to the rheological properties of the plastic melt, with melt viscosity being the key factor determining the magnitude of this pressure. Lower melt viscosity reduces flow resistance under the same process conditions, resulting in a more uniform pressure distribution within the mold cavity. Conversely, higher-viscosity melts generate greater local pressure. For example, PE melt has a relatively low viscosity, approximately 50-100 Pa · s at 200 °C . The pressure exerted on the core during cavity filling is relatively flat, typically peaking at 30-50 MPa . In contrast, PC melt has a viscosity of 500-1000 Pa · s at the same temperature , requiring higher injection pressure to propel it, resulting in local pressures on the core reaching 80-120 MPa. Furthermore, the non-Newtonian nature of the melt also influences pressure. Most plastic melts are pseudoplastic, with viscosity decreasing as shear rate increases. Therefore, changes in injection velocity can lead to significant pressure fluctuations. When the injection speed increases, the viscosity of the PE melt decreases significantly and the pressure increase is small; however, the PMMA melt is less sensitive to shear rate, and an increase in speed will directly lead to a significant increase in pressure, which requires special attention in mold design.

The temperature sensitivity of a plastic melt directly affects the pressure applied to the mold cavity and core. Different plastics exhibit significant variations in their viscosity response to temperature fluctuations, leading to noticeable differences in pressure. For highly temperature-sensitive plastics, such as PVC, a 10°C increase in temperature can cause a drop in melt viscosity by over 50%. Therefore, unstable barrel temperature control during the molding process can lead to dramatic fluctuations in pressure applied to the core. For example, PVC has a high viscosity at 170°C, exerting a pressure of up to 60 MPa on the core. However, at 180°C, the pressure can drop sharply to 35 MPa. Such fluctuations can easily lead to dimensional instability and flash in the molded part. In contrast, POM has a lower temperature sensitivity. Within the 190-210°C range, viscosity fluctuations are minimal, and pressure applied to the core is typically controlled within 5 MPa, resulting in a more stable molding process. Therefore, when setting process parameters, it is important to appropriately control the temperature differential based on the plastic’s temperature sensitivity. For materials like PVC, temperature fluctuations should be kept within ±2°C to minimize the impact of pressure fluctuations on the mold.

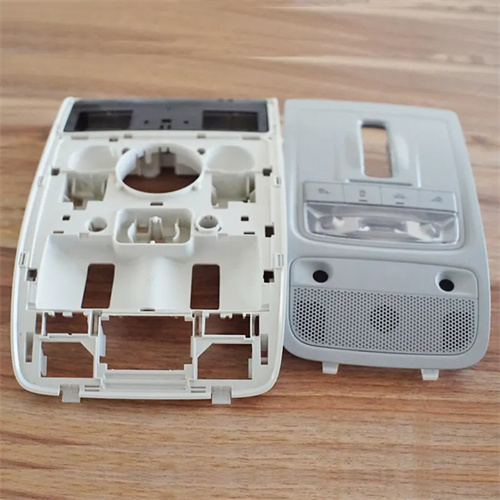

The structural characteristics of the plastic part and the geometry of the mold cavity result in different pressure distributions for different plastic melts during the filling process. For thin-walled, complex plastic parts, the melt flow path is long and has large cross-sectional variations. High-viscosity plastics are more likely to generate high pressures at corners or narrow gaps. For example, when ABS melt fills a 1mm-thick, grid-patterned cavity, the local pressure at the corner can reach 90 MPa, while the corner pressure of PE melt with the same structure is only 40 MPa. This difference stems from the different flow resistance caused by the different viscosities. The protruding portion of the core also experiences higher pressure. As the melt flows through the core, the flow cross-section shrinks, increasing the flow velocity. According to Bernoulli’s principle, this increase in dynamic pressure and static pressure also increases, creating a localized high-pressure zone. For hard and brittle plastics like PC, if the core corners are designed as right angles, the melt impact pressure can exceed 100 MPa, easily causing core deformation. However, using rounded corners can reduce this pressure by 20%-30%. Therefore, mold design needs to optimize the cavity structure according to the pressure characteristics of the plastic melt. For high-viscosity plastics, larger radius and smoother cross-sectional transitions should be used to reduce local high pressure.

The injection molding process parameters directly affect the pressure exerted by the melt on the mold cavity and core. Different plastics require different parameter combinations to maintain pressure within a reasonable range. Injection pressure is the most direct control method. For high-viscosity plastics such as PC and PMMA, higher injection pressures (80-120 MPa) are required to ensure complete filling, resulting in correspondingly higher pressure on the core. For low-viscosity plastics such as PE and PP, injection pressures of 30-60 MPa are typically sufficient, resulting in lower pressure on the core. The holding pressure and holding time also affect the final pressure. During the holding phase, the melt requires replenishment due to cooling and shrinkage. High holding pressures result in prolonged pressure on the core. For example, PA6 shrinks significantly after cooling after molding, requiring higher holding pressures (50-70 MPa) and longer holding times (15-20 seconds). This results in a total core pressure approximately 30% higher than that of PP parts. In addition, the adjustment of back pressure cannot be ignored. Properly increasing the back pressure can enhance the uniformity of melt plasticization, but too high back pressure will increase the reaction force of the melt on the screw, indirectly increasing the pressure on the cavity. Therefore, the back pressure needs to be balanced according to the type of plastic. For example, the back pressure of PC is usually set to 5-10MPa, while that of PE is set to 2-5MPa.

The varying pressures exerted by different plastic melts on the mold cavity and core place specific demands on mold material selection and structural strength design. For molds frequently processing high-viscosity, high-pressure plastics (such as PC and POM), the cavity and core must be constructed from high-strength alloy steels, such as H13 or S136, achieving a hardness of HRC45-50 after quenching to withstand long-term high-pressure impact without deformation. Furthermore, the cavity wall thickness must be increased, with reinforcing ribs and other structures employed to enhance overall rigidity. For example, the cavity wall thickness of a PC mold should be 20%-30% thicker than that of a PE mold. For molds processing low-viscosity plastics, lower-cost 45# steel or P20 steel with a hardness of HRC28-32 can meet operational requirements. Furthermore, the mold’s guiding and locking mechanisms must be designed based on pressure characteristics. High-pressure molds require larger-diameter guide pins and bushings and stronger clamping force. For example, a mold producing PC parts requires a clamping force of 400-600 tons, while a PE mold only requires 200-300 tons. Targeted design based on the pressure characteristics of the plastic melt can effectively extend mold life and reduce the risk of production failures.