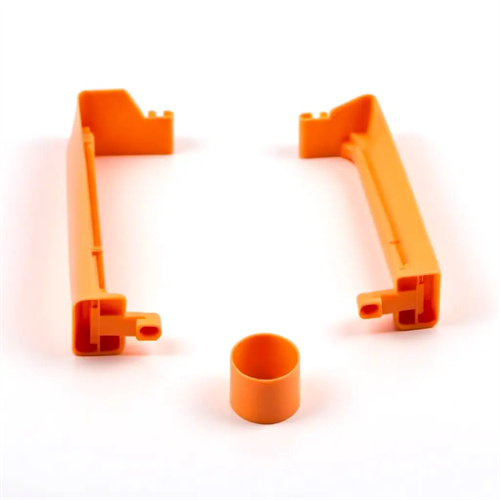

Injection molding mechanical clamping device

The mechanical mold clamping mechanism for injection molding is a key device that uses mechanical transmission to achieve mold opening, closing, and locking. Its core components include a toggle linkage, platen, tie rod, and drive components. Featuring a compact structure, stable clamping force, and low energy consumption, it is widely used in small and medium-sized injection molding machines (with clamping forces ranging from 50 to 5000 kN). The toggle linkage is the core of the mechanical mold clamping mechanism. By converting the motor’s rotational motion into linear motion of the platen through the extension and retraction of the toggle linkage, it enables rapid mold opening and closing and high-pressure locking. During mold closing, the motor drives the toggle linkage through a reduction gearbox to extend, pushing the moving platen toward the fixed platen. Once the mold is closed, the toggle mechanism straightens to its “dead center” position, amplifying the clamping force through its force-multiplying properties. For example, a 100 kN motor drive force can generate a 1000 kN clamping force, typically achieving a force amplification factor of 10-20 times. The hinge of the toggle mechanism adopts bearing connection to reduce movement friction, ensure smooth opening and closing of the mold, and respond quickly. The mold opening and closing speed can reach 0.5-1.5m/s, meeting the needs of efficient production.

The mold plate design for the mechanical mold clamping device of an injection molding machine must ensure sufficient rigidity and strength to withstand the reaction forces generated by the clamping force and injection pressure. The mold plate is typically made of HT300 gray cast iron or Q235 steel plate welded together. Large mold plates require aging treatment to eliminate internal stresses and prevent deformation after long-term use. The mold plate flatness error should not exceed 0.1mm/m, and the parallelism error (between the movable and fixed mold plates) should not exceed 0.15mm/m. This ensures uniform force distribution during mold closing, preventing flash on the plastic part or mold damage. The tie rod holes in the mold plate are precision bored, with a clearance of 0.05-0.1mm for the tie rods. The tie rods are secured to the mold plate with nuts. The tie rods are made of 40Cr, quenched and tempered (HB250-280), and chrome-plated for rust resistance. The diameter is determined by the clamping force. For example, for an injection molding machine with a clamping force of 1000kN, the tie rod diameter should be 60-80mm to ensure sufficient load-bearing capacity. Mold installation holes and positioning holes must also be set on the template. The diameter of the positioning hole is 0.1-0.2mm larger than the mold positioning ring and the depth is 20-30mm to ensure accurate mold installation and positioning.

Adjusting the clamping force of a mechanical injection molding machine is a key function for adapting to the needs of different molds and parts. This is achieved by adjusting the relative position of the movable platen and the toggle mechanism. Common adjustment methods include mechanical and electric. Mechanical adjustment changes the toggle length by rotating an adjusting nut. Each rotation can vary the clamping force by 5%-10%, making it suitable for small injection molding machines. Electric adjustment uses a servo motor to drive a ball screw to adjust the toggle position, offering higher accuracy (±1%) and faster response, making it suitable for medium- to large-scale injection molding machines. The clamping force setting must be calculated based on the projected area of the part and the melt pressure. The formula is: Clamping Force (kN) = Projected Area (cm²) × Melt Pressure (MPa) × Safety Factor (1.2-1.5). For example, for a part with a projected area of 500 cm² and a melt pressure of 40 MPa, the required clamping force is 500 × 40 × 1.3 = 26,000 kN. Therefore, an injection molding machine with a clamping force of at least 26,000 kN should be used. When adjusting the clamping force, it is necessary to ensure that the four tie rods are evenly stressed, with a force difference of no more than 5%. This can be achieved by measuring the elongation of the tie rods or monitoring with strain gauges to avoid deformation of the mold due to uneven force .

The safety protection system for injection molding machine clamping devices is a crucial component for ensuring the safety of both equipment and operators. It comprises both mechanical and electrical protection components. The mechanical protection features include a safety door, hydraulic overload protection, and platen bumpers. The safety door utilizes an interlocking mechanism, ensuring mold closing can only be performed after the door is closed, preventing operators’ hands from entering the danger zone. The hydraulic overload protection releases pressure via a pressure relief valve when the clamping force exceeds the set value by 10%, preventing overload damage to mechanical components. The platen bumpers, mounted on the edges of the movable and fixed platens and made of an elastic material (such as polyurethane) with a thickness of 20-30mm, mitigate the impact of platen collisions. Electrical protection is implemented through travel switches, pressure sensors, and a PLC control system. Upon detecting an abnormality (such as an open safety door or abnormal clamping force), the clamping power is immediately cut off, operation is stopped, and an alarm is issued. For example, when a foreign object in the mold caused a sudden increase in clamping force on an injection molding machine during mold closing, the pressure sensor detected the abnormality and the system stopped the mold closing within 0.1 seconds, preventing damage to the platen and tie rods.

Maintenance and care for injection molding machine clamping devices are crucial to extending equipment life and ensuring operational accuracy. Key components require regular inspection and lubrication. The hinge bearings of the toggle mechanism should be relubricated with lithium-based grease every 100 hours of operation to ensure smooth movement and reduce wear. The tie rods and adjusting nuts should be inspected every 500 hours, loose nuts tightened, threads cleaned of dirt, and rust-proof oil applied. The platen guide sleeves should be inspected every 300 hours. If wear causes a clearance exceeding 0.2mm, they should be replaced promptly to ensure smooth platen movement. Regular clamping force calibration is required. After every 1000 molds or mold changes, the actual clamping force should be measured using a dedicated instrument. The deviation from the set value should not exceed 5%, otherwise readjustment is required. For example, the toggle mechanism of an injection molding machine, worn due to long-term use, resulted in a 10% deviation in clamping force. By replacing the bearings and readjusting, the clamping force accuracy was restored to within ±3%. Furthermore, the clamping device must be kept clean, and plastic debris and oil stains on the platen surface should be regularly removed to prevent impurities from entering the moving parts and affecting precision. Through scientific maintenance, the service life of the mechanical clamping device can reach more than 10 years, and the operating accuracy remains stable.