General process of injection mold design and drawing

Injection mold design and drafting are crucial steps in transforming product requirements into mold entities. This process encompasses the entire process, from product analysis to mold assembly drawing creation. Each step must strictly adhere to design specifications and process requirements. A scientific and rational design process can improve mold design efficiency, reduce rework, and ensure that the mold meets molding process and production requirements. Mold design and drafting typically involves five phases: product analysis, structural design, component design, assembly drawing creation, and drawing review. These phases are closely linked to form a complete design cycle.

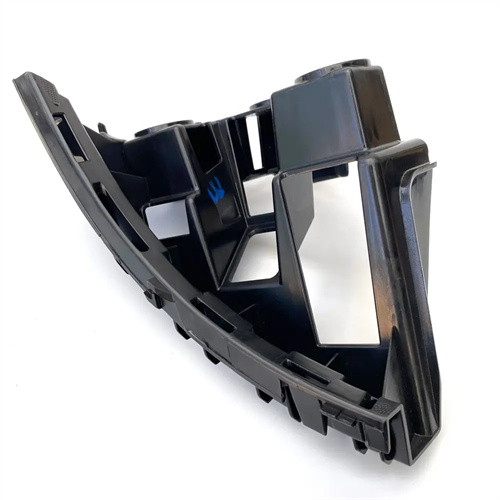

Product analysis is the first step in mold design and drafting, requiring a comprehensive analysis of the plastic product’s structure, dimensional accuracy, material properties, and molding requirements. First, the 3D model of the product is reviewed to check for defects that could affect molding, such as undercuts, uneven wall thickness, and sharp corners. For example, a plastic housing with a 0.5mm wall thickness difference requires optimization by adding reinforcing ribs or adjusting the gate position. Next, the plastic material’s shrinkage, fluidity, and molding temperature are analyzed. For example, polyethylene (PE) shrinks between 1.5% and 3.5%, requiring allowance for shrinkage in the mold design. Finally, the product’s accuracy level is determined, such as dimensional tolerances of IT12 to IT14 and surface roughness of Ra1.6 to 3.2μm. This provides a basis for subsequent mold tolerance design. The product analysis phase also involves creating a 2D engineering drawing of the product, noting key dimensions, geometric tolerances, and technical requirements. This serves as the initial basis for mold design.

Structural design is a core component of mold design, encompassing the determination of the number of cavities, parting surface selection, gate design, ejector mechanism design, and cooling system design. The number of cavities is determined by the production batch size and the tonnage of the injection molding machine. Large batch sizes utilize multiple cavities (e.g., 8 or 16 cavities), while smaller batch sizes utilize a single cavity. The parting surface should be located at the part’s largest contour to ensure smooth demolding. For example, radial parting is used for cylindrical parts, while flat parting is used for box-shaped parts. Gate design should be tailored to the part’s structure. Point gates are suitable for products with high aesthetic requirements, while side gates are suitable for small and medium-sized parts. Ejector pins are preferred for ejection mechanisms, while ejector plates or inclined ejectors are used for complex parts. The cooling system should ensure uniform temperature, with water channels measuring 8-12mm in diameter and spaced 30-50mm apart. During the structural design phase, a rough sketch of the mold structure is drawn to determine the layout and connection of the various components. For example, a mobile phone case mold utilizes a single-cavity design with a latent gate, a combined ejector pin and ejector plate, and cooling channels arranged around the cavity.

Part design, based on structural design, involves detailed design of all mold components, including the cavity, core, mold plate, guide pins, and guide bushings. The cavity and core are 3D-modeled based on the part’s 3D model, with shrinkage factored into the dimensions. For example, if the part is 100mm and the shrinkage factor is 2%, the cavity size is set to 102mm. The thickness and strength of mold plate components must be calculated. The thickness of the mold plate is determined based on the cavity depth and clamping force, generally two to three times the cavity depth. Standard parts (such as guide pins and ejector pins) are directly based on national or factory standards. Non-standard parts require detailed 3D models. Part design requires annotation of key dimensions, tolerances, and materials. For example, the mold cavity material is 718H with a hardness of 35-40 HRC, and the guide pin material is 20CrMnTi with a carburized and quenched HRC of 58-62. Furthermore, part strength and stiffness verification is required. For example, ejector pin diameter calculation requires: ejector diameter ≥ √(4 × ejection force ÷ π × material allowable stress) to ensure that the part does not deform or break during operation.

Assembly drawings involve assembling all parts according to their assembly relationships to form a complete mold assembly diagram, including front, top, cross-sectional, and exploded views. These drawings must clearly depict the positional relationships and fit requirements of each part, noting key parameters such as mold closing height, maximum mold opening distance, and mounting dimensions. For example, a mold closing height of 350mm, a mounting hole spacing of 200×200mm, and compatibility with a 200-ton injection molding machine are specified. Mating parts must be marked with tolerances, such as H7/h6 for guide pins and guide bushings and H7/m6 for the cavity and mold plate. Moving parts must also have strokes specified, such as 50mm for the ejector mechanism and 30mm for the core puller. Assembly drawings must also include a parts list, listing part name, quantity, material, and standard number, to facilitate part processing and costing. For example, a mold assembly drawing may contain 58 parts, including 32 standard parts and 26 non-standard parts. The parts list clearly identifies each part’s parameters, providing a basis for production preparation.

Drawing review is the final step in mold design and drafting. It requires a joint review by design, process, and manufacturing professionals to ensure the accuracy and feasibility of the drawings. This review includes: product structure optimization, mold structure rationality, accurate part dimensions, appropriate tolerances, suitable material selection, and process feasibility. For example, a review may reveal that the corner radius of a cavity is too small (R0.5mm), making it difficult to process and requiring a change to R1mm; or that uneven ejector pin placement may cause part deformation during ejection, requiring the addition of two ejector pins. After passing the review, the drawings must be signed and confirmed before they can be released for production. Both electronic and paper copies must be retained for archiving. For complex molds, mold flow analysis (CAE) is also required to simulate melt filling, cooling, and warpage, optimizing the mold structure. For example, if analysis reveals weld lines on a part, the gate location and number may need to be adjusted to ensure molding quality. Only by strictly following the design and drafting process can high-quality mold drawings be produced, laying the foundation for mold manufacturing and production.