Heater on injection hot runner plate and its assembly

The heater on an injection molding hot runner plate is a core component that maintains a stable melt temperature within the runner. Its performance and assembly quality directly impact the hot runner system’s temperature control accuracy, energy consumption, and service life. The hot runner plate heater must provide uniform and stable heat to compensate for heat loss, ensuring good melt flow within the runner and preventing problems such as gate blockage and product defects caused by temperature fluctuations. Choosing the right heater type, accurately calculating power parameters, and scientifically designing the assembly structure are key to ensuring efficient hot runner system operation.

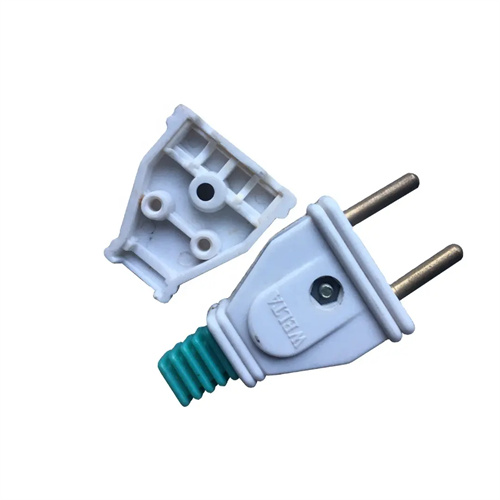

Hot runner plate heaters can be categorized by mounting method into rod, tubular, and membrane types, each with its own application scenarios. Rod heaters ( 6-12mm diameter) are suitable for heating deep holes in hot runner plates. They are inserted into the plate holes with an interference fit ( 0.05-0.1mm ). They offer high heat transfer efficiency (thermal conductivity ≥ 80W/(m・K) ) and a power density of 15-25W/cm² , making them suitable for small and medium-sized hot runner plates. For example, a four- cavity hot runner mold utilizes six 8mm diameter rod heaters, each with a power output of 500W . These heaters are evenly distributed within the plate, achieving a temperature control accuracy of ±1 °C. Tubular heaters ( 8-16mm diameter ) feature a U -shaped or annular structure, placed over the outside of the runner plate or embedded in a groove. They are easy to install and offer a power density of 10-15W/cm², making them suitable for large hot runner plates. For example, a certain automotive bumper hot runner plate utilizes two annular tubular heaters, totaling 6kW, to achieve uniform heating over a large area. Membrane heaters (0.5-2mm thickness) feature a flexible structure that can conform to complex runner plate surfaces. With a power density of 8-12W/cm², they are suitable for special-shaped runner plates, but have poor temperature resistance (≤250°C) and are therefore suitable for low-temperature plastics (such as PE and PP).

The power calculation of the heater needs to be determined based on the heat loss of the hot runner plate, including the conduction loss to the mold template, the radiation loss to the air and the heat taken away by the melt. The calculation formula is: Total power P = ( P1+P2+P3 )× A safety factor ( 1.2-1.5 ) is used, where P1 represents conduction loss (related to the contact area between the runner plate and the mold plate, and the temperature difference), P2 represents radiation loss (related to the runner plate surface area and the ambient temperature), and P3 represents the heat removed by the melt (related to the injection volume and the melt’s specific heat capacity). For example, a hot runner plate weighs 5 kg (the specific heat capacity of steel is 0.46 kJ/(kg・℃ ) ), operates at a temperature of 200 ℃, and has an ambient temperature of 25 ℃. Conduction and radiation losses are approximately 1500 W , and the melt removes approximately 800 W of heat per hour . Therefore, the total power P = (1500 + 800) × 1.3 ≈ 2990 W. A 3.5 kW heater is typically used. The power distribution must match the runner layout, and the power density near the gate should be increased by 20%-30% to compensate for local heat losses.

Heater assembly accuracy directly impacts heat transfer efficiency and service life. The clearance between the rod heater and the manifold plate hole must be strictly controlled, with an interference fit of 0.05-0.1mm to ensure close contact. During assembly, the heater should be cooled by liquid nitrogen or the manifold plate should be heated (80-100°C) to avoid damage from hard knocks. Holes must be machined to H7 accuracy, with a surface roughness of Ra ≤ 1.6μm. The bottom of the hole should be chamfered (R1-2mm) to prevent stress cracking at the heater end. For example, the heater mounting hole diameter on a hot runner plate is 10H7 (10-10.015mm), the heater diameter is 10.06-10.07mm, and the interference fit is 0.045-0.07mm. After heating the manifold plate to 100°C, the heater can be installed smoothly, achieving heat transfer efficiency exceeding 90% . The clearance between the tubular heater and the groove of the flow channel plate must be ≤ 0.5mm . The gap should be filled with thermal grease (thermal conductivity ≥ 1.5W/(m・K) ) to enhance heat transfer and fastened with stainless steel tape to prevent loosening.

Heater temperature control and wiring must be designed to be safe and reliable. Each heater should be equipped with an independent thermocouple (accuracy ±1°C) located 5-10mm from the heater for real-time temperature monitoring. The thermostat uses PID control with an accuracy of ±1°C to prevent overheating that could cause heater burnout or plastic decomposition. Wiring terminals should be made of high-temperature-resistant materials (temperature resistance ≥300°C), such as ceramic or silicone rubber insulation. Conductors should use high-temperature-resistant cable (temperature resistance 200-300°C). The cross-sectional area should be selected based on the current (current carrying capacity of 3-5A per square millimeter). For example, a 2kW heater (220V) with a current of approximately 9A would require 2.5mm² cable. The junction box should be sealed and waterproof to prevent the ingress of oil, dirt, and moisture. It should be located in a non-moving area of the mold for easy access and maintenance. For example, the junction box in a hot runner system is mounted on the side of the fixed mold base plate and has a built-in terminal block and fuse (rated at 1.5 times the operating current) to ensure electrical safety.

Heater maintenance and life extension measures require special attention. Regularly check the heater’s insulation resistance (≥50MΩ) to prevent leakage. Clean carbon deposits and impurities from the heater surface every 10,000 molds, and use fine sandpaper (800#) to polish the oxide layer to restore heat transfer performance. For rod-type heaters, if localized overheating (detected by an infrared thermometer) is observed, it may be due to poor contact with the runner plate and requires reinstallation and refilling with thermal grease. Heaters typically have a service life of 10,000 to 30,000 hours. After exceeding this lifespan, the entire heater must be replaced to prevent temperature fluctuations caused by localized damage. For example, a hot runner heater on a production line experienced a 15% power drop after 20,000 hours of use. After replacing the new heater, runner temperature stability was significantly improved, and weld mark defects on the parts were reduced by 80%. Through scientific selection, precise assembly, and regular maintenance, hot runner plate heaters can provide long-term stable operation, ensuring the efficient operation of the hot runner system.