Injection molding shot size

Injection molding shot size refers to the maximum volume or weight of plastic melt that an injection molding machine can inject into the mold cavity during a single injection. It is an important parameter for measuring the capacity of an injection molding machine and directly determines the maximum size and weight of moldable plastic parts. The shot size must match the volume of the plastic part. If the shot size is too large, the melt will remain in the barrel too long, making it prone to degradation. If the shot size is too small, the cavity will not be filled, resulting in material shortage defects. In actual production, the choice of shot size must not only consider the weight of the plastic part, but also the characteristics of the plastic, the structure of the mold, and the molding process parameters. Through precise control, stable product quality and maximum production efficiency are ensured.

Theoretical calculations of shot weight are based on the part’s volume and density, taking into account the actual part structure and the mold’s runner system volume. First, calculate the part’s volume (including the sum of all cavities) based on the 3D model. Add the volume of the runner system, including the runners and gates, to arrive at the total shot volume. The volume is then converted to weight based on the plastic’s density (e.g., PP has a density of approximately 0.9 g/cm³, and ABS has a density of approximately 1.05 g/cm³). Total shot weight = total shot volume × plastic density. To ensure shot weight stability, the maximum shot weight of the selected injection molding machine should be between 1.3 and 2.0 times the calculated total shot weight. For example, if the total shot weight is 100 g, a machine with a maximum shot weight of 130-200 g should be selected. This range avoids uneven plasticization caused by an injection volume approaching the machine’s maximum capacity, while also preventing energy waste and reduced production efficiency caused by an injection volume that is too small. In addition, for crystalline plastics, the effect of shrinkage on volume needs to be considered, and a 1%-3% margin should be appropriately added during calculation.

The injection volume of an injection molding machine is primarily determined by the screw’s structural parameters and working stroke. The screw’s diameter, effective length, and maximum stroke directly affect the volume of melt that can be delivered in a single shot. According to the formula: Injection volume = π × (screw diameter / 2)² × maximum screw stroke × 0.85 (correction factor), the larger the screw diameter or the longer the stroke, the greater the injection volume. Therefore, large-scale injection molding machines are typically equipped with larger-diameter screws to meet the injection requirements of large plastic parts. For example, an injection molding machine with a 50mm screw diameter and a maximum stroke of 200mm has a theoretical injection volume of approximately 330cm³ (approximately 300g of PP material), suitable for molding parts weighing 150-200g. The screw’s compression ratio and screw groove depth also indirectly affect the stability of the injection volume. An excessively high compression ratio can increase the amount of melt backflow and reduce the actual injection volume. A shallow screw groove can limit the melt delivery rate and reduce injection efficiency. Therefore, when selecting an injection molding machine, it is important to comprehensively evaluate all screw parameters to ensure they match the required injection volume.

The properties of plastics significantly influence the actual injection volume. Variations in melt viscosity and fluidity among different plastics can lead to different actual injection volumes under the same injection parameters. High-flow plastics (such as PE and PP) exhibit low melt resistance during injection, resulting in actual injection volumes closer to theoretical values at the same screw speed and injection pressure. Low-flow plastics (such as PC and POM), on the other hand, exhibit high melt viscosity and flow resistance, leading to actual injection volumes that may be 5%-10% lower than theoretical values. This may require increasing injection pressure or extending injection time to compensate. For example, when molding PC parts, if theoretical calculations call for a 100g injection volume, an actual injection volume of 105-110g may be required to overcome flow losses caused by the high viscosity. Furthermore, the thermal stability of the plastic can also limit the choice of injection volume. Heat-sensitive plastics (such as PVC) are susceptible to degradation if they remain in the barrel for too long. Therefore, the actual injection volume should not be less than 40% of the injection molding machine’s maximum injection volume to minimize melt residence time in the barrel and prevent degradation.

Injection volume control accuracy is crucial to the stability of product quality. Even slight fluctuations in injection volume can lead to dimensional or weight deviations in the product. Injection molding machines typically adjust injection volume by controlling the screw’s injection stroke. This stroke control accuracy can reach ±0.1mm, resulting in injection volume deviations within ±0.5%. During production, injection volume calibration is required regularly. The melt weight is measured during multiple injections, and the screw stroke is adjusted to the set value. For example, if the injection volume is set to 100g, 10 consecutive injections are performed, and the melt weight is measured each time. If the average value deviates from the set value by more than 1%, the maximum screw stroke is adjusted until the accuracy requirement is met. Furthermore, the matching of injection speed and pressure can affect injection volume stability. High-speed, high-pressure injection creates a greater inertial force in the melt, making overshot more likely. Low-speed, low-pressure injection can lead to smaller injection volumes due to insufficient filling. Therefore, process parameters must be optimized to optimally match injection volume with injection speed and pressure to ensure consistent melt volume for each shot.

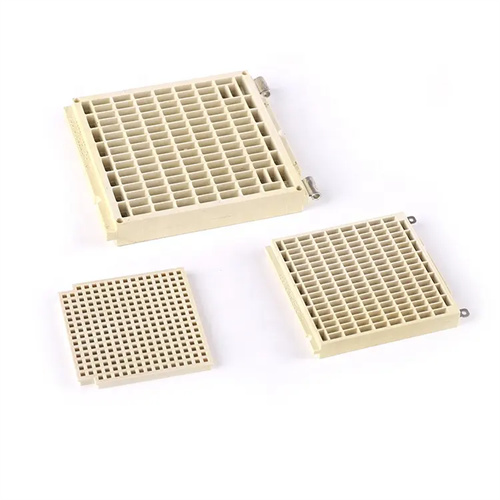

Injection volume is closely linked to molding cycle and energy consumption. Choosing the right injection volume can improve production efficiency and reduce energy consumption. Excessively large injection volumes prolong the melt’s plasticization time in the barrel, increasing the molding cycle and energy consumption of the motor and heating system. Excessively small injection volumes reduce the injection molding machine’s load factor, significantly increasing energy consumption per unit product. For example, using an injection molding machine with a maximum injection volume of 500g to produce a 50g part consumes 1.5-2 times the energy of a 200g machine. Therefore, in mass production, the appropriate injection molding machine should be selected based on part weight, ensuring that the actual injection volume reaches 50%-80% of the machine’s maximum injection volume. This achieves optimal energy efficiency and keeps the molding cycle within a reasonable range. For multi-cavity molds, the total injection volume must be within this range. Optimizing runner design and process parameters ensures consistent fill levels across cavities, further improving production economy and ensuring consistent product quality.